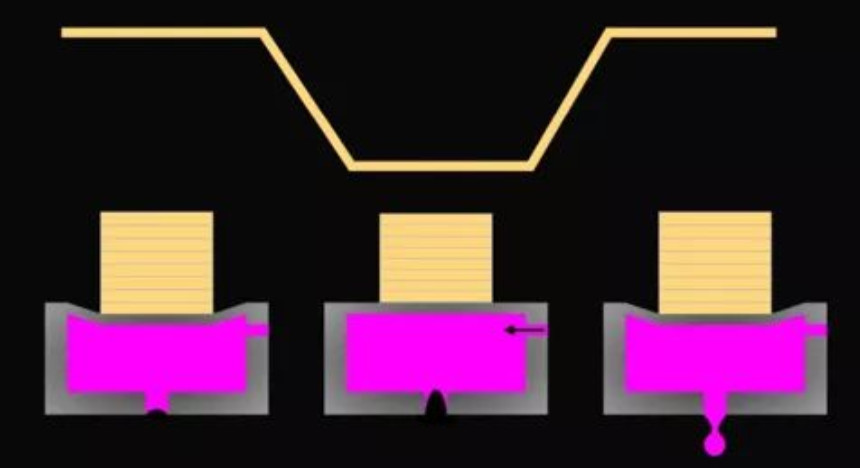

(2)Whether the printing waveform and voltage of the ink match.(3)Whether the ink can print soft and hard materials at the same time.

Why choose ink provided by UV printer manufacturers?

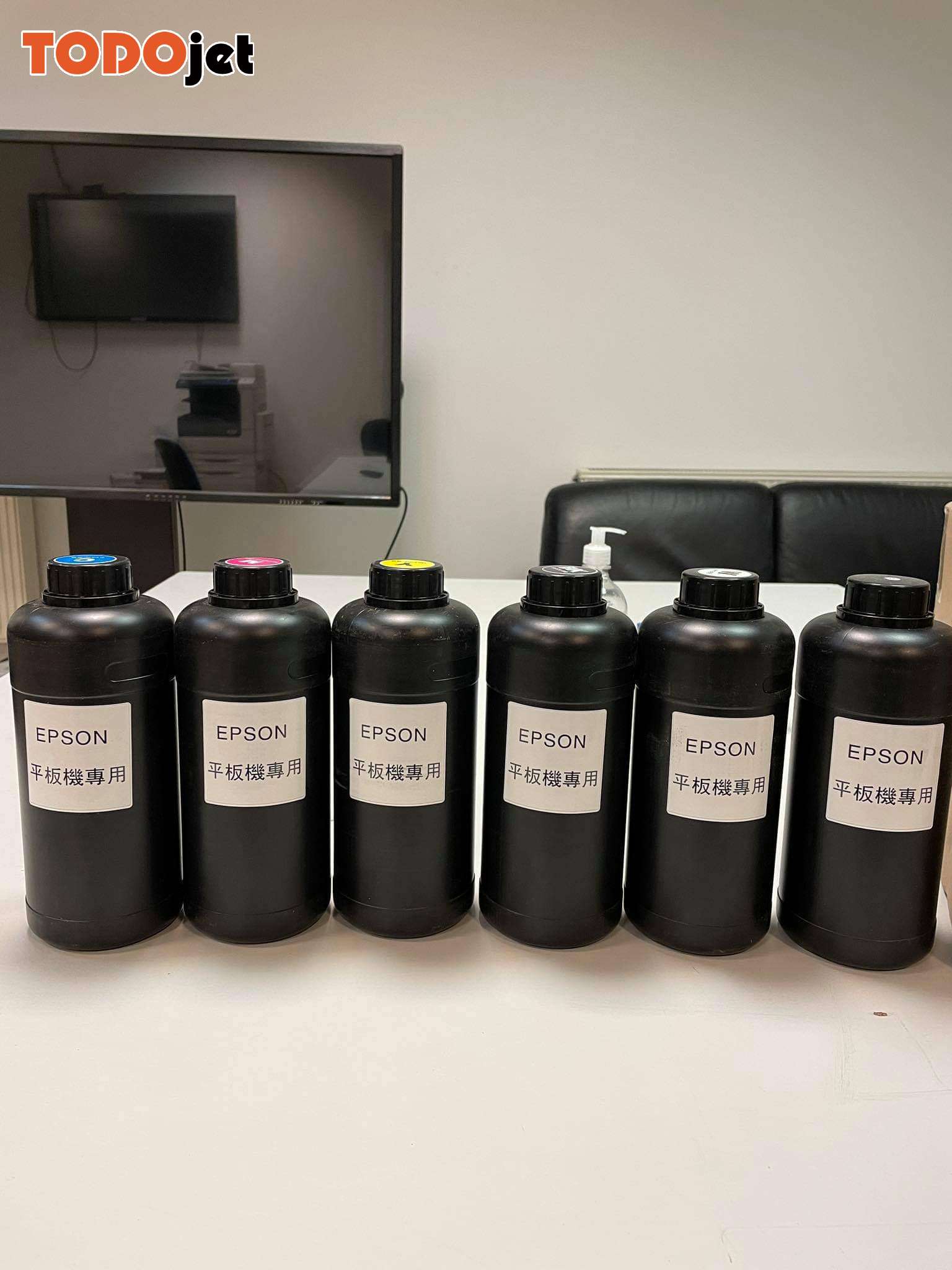

Different printing materials use different inks. There are many ink manufacturers in the market, flooded with various brands. Each manufacturer’s ink specifications and materials are different, and the quality is also uneven.

When you buy a UV printer, all the components are installed, which means that the machine can be put into production. For UV printing equipment, the most used consumable is ink. Different printing materials use different inks. There are many ink manufacturers in the market, flooded with various brands. Each manufacturer’s ink specifications and materials are different, and the quality is also uneven.

Most of UV printer manufacturers recommend that buyers buy the specified ink from them, why is this?

1.Protecting the print headThis is often one of the reasons. In daily use, problems with the print head are often related to ink. The print head is a very important part of the UV printer. The print heads on the market are basically imported. If it is damaged, there is no way to repair it. This is why the print head is not covered by the warranty. Ink density and materials affect printing speed and effect, and ink quality affects the life of the nozzle.If the life of the print head is shortened due to poor ink quality, it will affect the brand reputation of the manufacturer. Therefore, the manufacturer attaches great importance to the ink. The specified ink has been repeatedly tested. The ink and the print head have good compatibility. Long-term use can prove the reliability of the ink.

1.Protecting the print headThis is often one of the reasons. In daily use, problems with the print head are often related to ink. The print head is a very important part of the UV printer. The print heads on the market are basically imported. If it is damaged, there is no way to repair it. This is why the print head is not covered by the warranty. Ink density and materials affect printing speed and effect, and ink quality affects the life of the nozzle.If the life of the print head is shortened due to poor ink quality, it will affect the brand reputation of the manufacturer. Therefore, the manufacturer attaches great importance to the ink. The specified ink has been repeatedly tested. The ink and the print head have good compatibility. Long-term use can prove the reliability of the ink.

2.ICC curves.

(2)Whether the printing waveform and voltage of the ink match.(3)Whether the ink can print soft and hard materials at the same time.