The printing industry has experienced a rapid grouth in recent years. The primary characteristic of DTF is that it enables the freedom of using diverse fabric. The DTF printing machines are compatible with various materials and produce colorful and durable designs. In addition, DTF printers are now a realiable and cost-effective machine to own. Let’s have a look at this new technology and find out what DTF can do for you.

What is direct to film process?

Direct-to-film printing is an advanced method of directly transferring designs from films to fabrics. The process is an innovative alternative to screen-printing but is faster and more efficient in practice. Unlike the DTG which only works on cotton fabric, DTF method can work on not only cotton, but silk,poly blends, canvas, silk, polyester, nylon, denim etc.

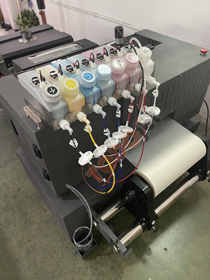

What is a printer DTF?

As the name suggests, a direct-to-film printer allows you to print a pattern on PET film and transfer it onto fabric directly, such as cotton, nylon, denim, silk, canvas etc. The key reason why the DTF printer is gaining attention is the freedon it gives you to choose almost all kinds of fabrics.

How does a DTF printer work?

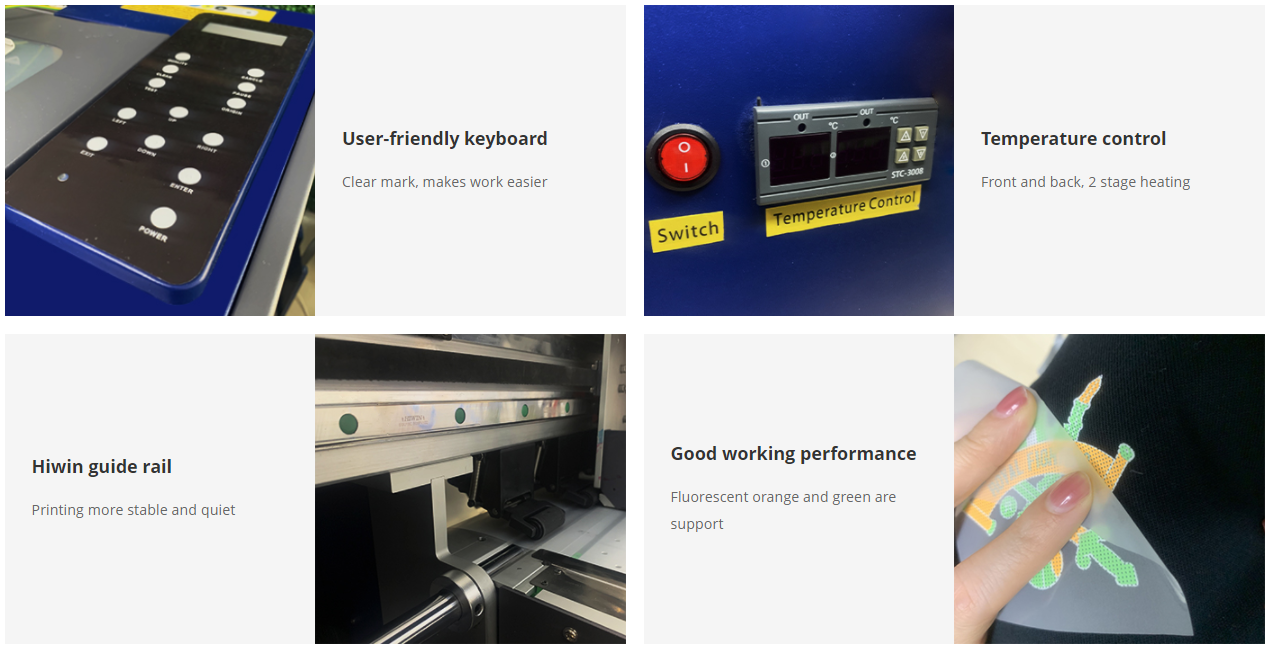

DTF printer does not require a heavy investment whether you are going to start a new business or wish to expand your business. It is definitely worth your time to take a closer look at this DTF printer.

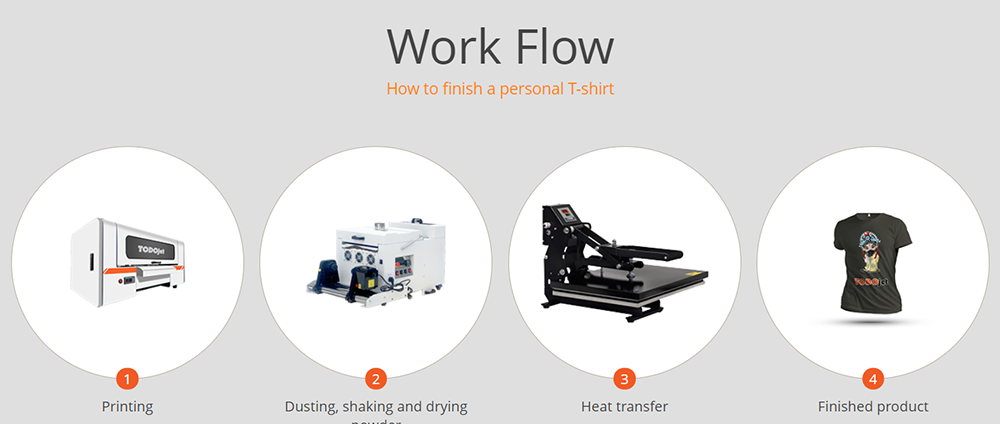

1.Print on film: input the image into the RIP software, usually are Maintop or Photoprint. Print the whole image on the PET film.

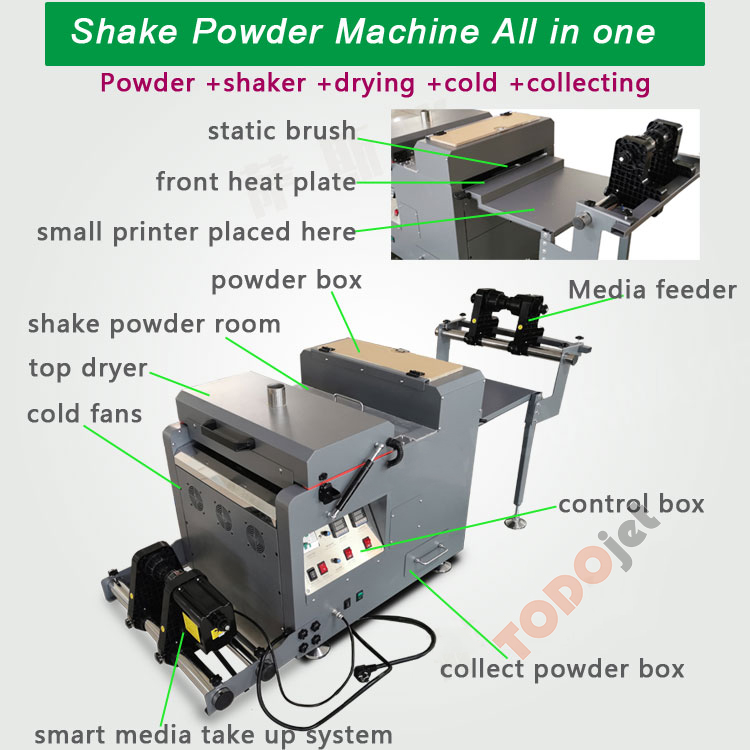

2.Powdering: with or without a powder shake macine to spread the hot melt powder evenly on the film when the ink is wet, remove the excessive powder carefully. Our powder shake machine can convey the material by the guide belt, which can be cut while printing.

3.Melt the powder: this step can be done in various ways. The most common way is to put the film with the printed image and powder in the curing oven and heat. If curing oven is not available, place the film inside the heat press, bring the top of the heat press very close to the film with a gap 4-7mm without touching it.

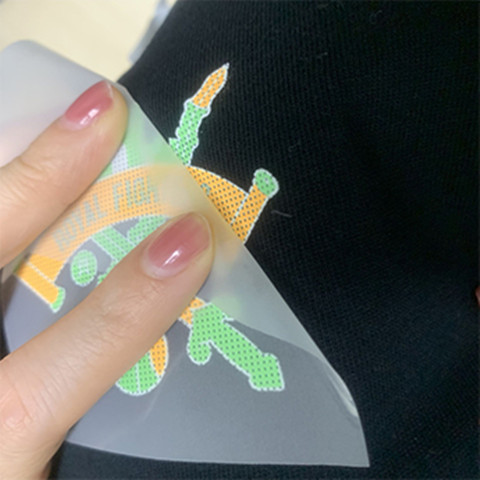

4.Heat press and transfer: put the film inside the heat press at a temperature range of 160-170 degree Celsius for 15-20 seconds. The film is now firmly attached to the fabric and you get the finished product.

Why Choose Us?

1.Are you Factory or Trading company?

We are Factory (Manufacturer).

2.Who are we?

We are based in Henan, China, starting from 2014, selling to South America(27.00%),Domestic Market(20.00%),Western Europe(15.00%),Mid East(8.00%),Southeast Asia(7.00%),Eastern Europe(5.00%),Eastern Asia(5.00%),South Asia(5.00%),Central America(3.00%),Southern Europe(2.00%),Oceania(1.00%),Africa(1.00%),Northern Europe(1.00%).

3.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

4.Why should you buy from us not from other suppliers?

Zhengzhou Domax is a professional manufacturer engaged in R&D, production and sale of digital printers. We specializing in research, manufacture, sale and service of UV printer,DTF printer,and other inkjet printing machines and related consumables.

5.What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish.