Why the UV flat printer occur material pattern poor adhesion ?

The poor adhesion of the material pattern of the UV flatbed printer is a headache. The printed pattern is peeled off with a slight scratch. Even if the printing effect is even better, it has no shelf life and practicality. There are six reasons for this: temperature and humidity relations, ink deterioration, material problems, UV lamp problems, too fast speed,the ink is not dry, and residual cleaning liquid.

1, UV flatbed printer temperature and humidity relationship

Solution: When the UV flatbed printer’s working environment is too low, especially in winter, the printed pattern is prone to cracking and peeling.If installation of air conditioners in the workshop is required to keep the indoor temperature above 15 °C. At the same time, avoid a humid environment. When the humidity in the air exceeds 70%, the moisture can easily condense on the printed material, resulting in poor adhesion.

2, UV flatbed printer ink deterioration

Solution: Under normal circumstances, the shelf life of UV flatbed printer ink is one year. When stored incorrectly, it is easy to shorten the shelf life of UV ink, resulting in precipitation, condensation, etc. After opening the bottle cap to find out this situation, Replace with new UV ink immediately.

3, UV flatbed printer printing material problems

Solution: different types of UV inks are different when printing with different material . Some need to use hard UV inks, some need soft UV inks, and some need neutral UV inks. Under the premise that it is not clear which UV ink is better for the material you printed, you may wish to consult the original UV flatbed printer manufacturer.

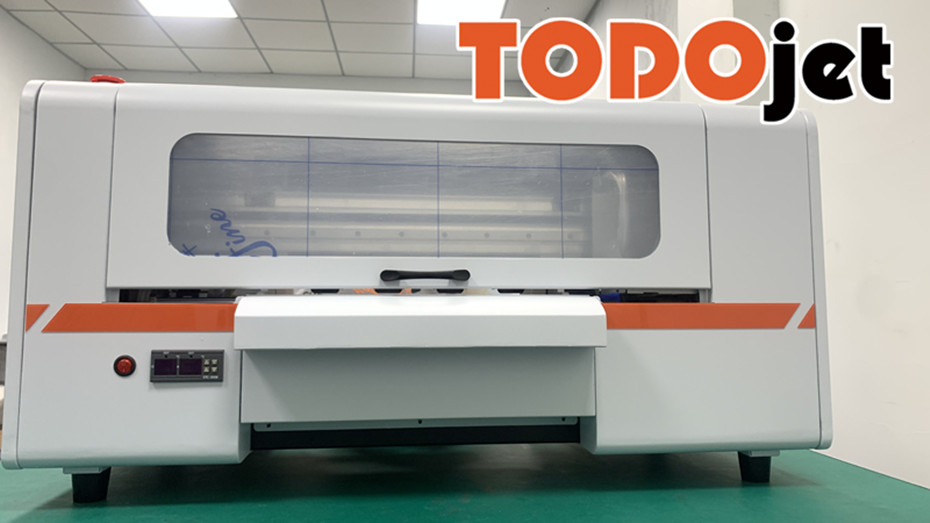

4, UV flatbed printer UV light problem

Solution: When the power of the UV lamp of the UV flatbed printer is too low, it will lead to incomplete curing of the UV ink on the surface of the material. At this time, the power of the UV lamp needs to be increased. If increasing the UV lamp power is not enough, you need to replace the UV lamp with a higher power.

5.UV flatbed printer is too fast or the ink is not dry

Solution: When the UV flatbed printer prints in both directions at high speed, the time left for the UV lamp to illuminate is very short. At this time, the ink will not dry thoroughly, and the printing speed needs to be appropriately reduced.

6, UV flatbed printer has cleaning fluid residue

Solution: The surface of some materials needs to be wiped with a cleaning fluid to keep it clean and remove static electricity. At this time, the waiting time is longer. After the cleaning fluid is dry, it can be printed with a UV flatbed printer.