In the dynamic world of digital textile printing, Direct-to-Film (DTF) technology has emerged as an innovative technology that offers a seamless way to achieve vibrant, high-quality prints on a variety of fabrics. Whether you are an experienced professional or new to the world of textile printing, mastering the art of vibrant fabric printing with DTF technology opens up a world of creative possibilities. Let's take a look at some of the key steps to achieving great results.

Understanding the Basics of DTF Technology

DTF technology uses special printers and inks to print vibrant designs directly onto fabric. Unlike traditional methods, DTF allows for intricate detail and a wide range of colors, making it ideal for personalized apparel and home textiles.

Choosing the Right DTF Printer and Ink

The foundation for achieving vibrant fabric prints lies in selecting the right DTF printer and compatible inks. Make sure your printer is equipped with the latest technology and features for precision and color accuracy. High-quality DTF inks are formulated to bond seamlessly with fabrics and provide long-lasting, vibrant results.

Optimizing Your Design for DTF Printing

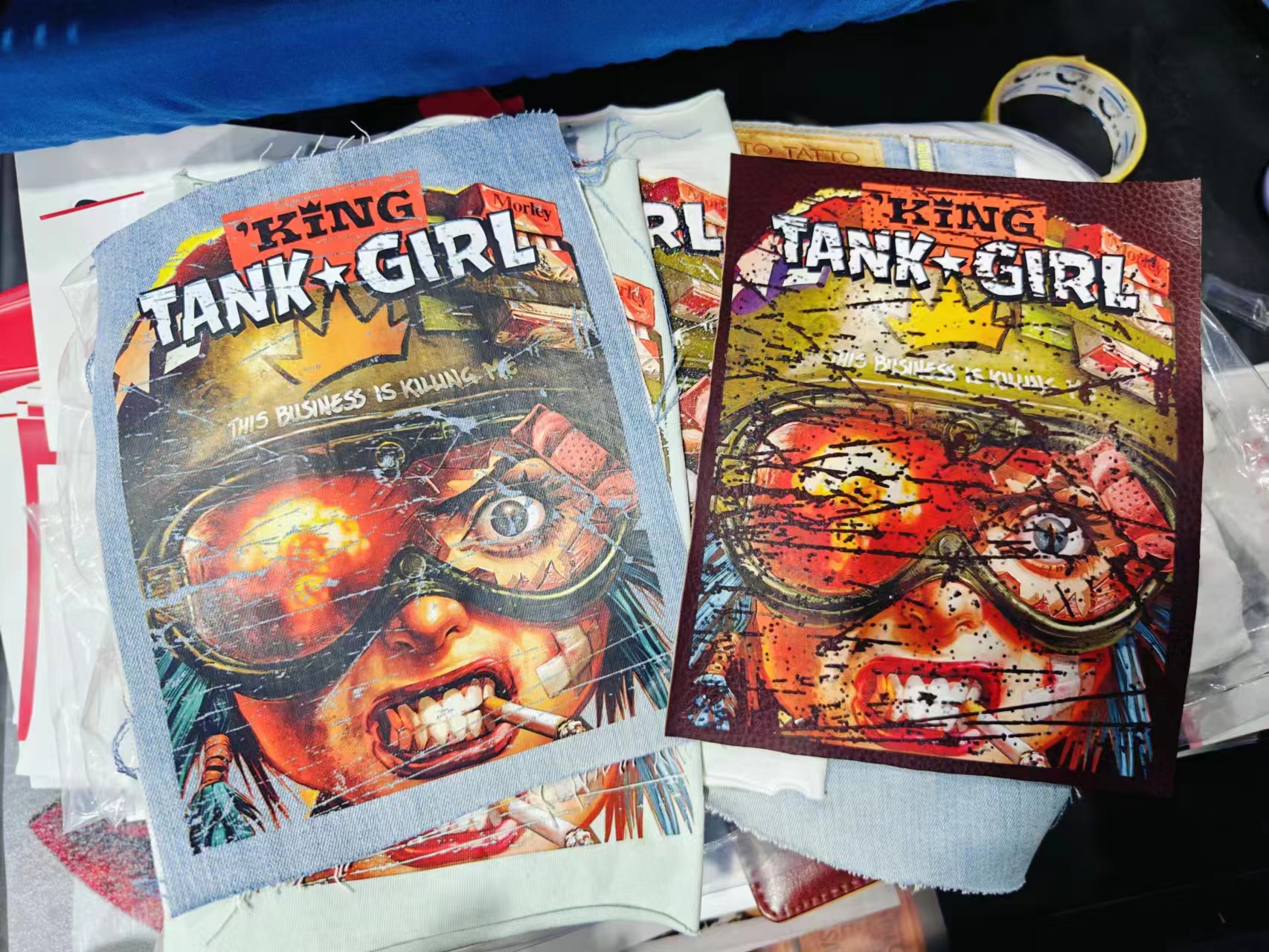

Optimize your design for DTF printing before you press the print button. Consider fabric type, color, and texture to enhance the final output. High-resolution images and vector graphics work very well and ensure that every detail is captured during the printing process.

Proper preparation of the fabric

Prepare the fabric by making sure it is clean and free of residue. Proper fabric pretreatment improves ink absorption and color vibrancy. Pretreatment methods may vary by fabric type, so it is important to follow the manufacturer's guidelines.

Calibration and Color Management

Calibrating a DTF printer is an important step in achieving consistent, vibrant prints. Ensure that the color profile is set correctly to reproduce the desired hue. Regularly adjusting your printer will help maintain color consistency aacross different print runs.

Experiment with different fabrics.

DTF technology is versatile and suitable for a wide variety of fabrics. Experimenting with different types of fabrics yields unique and visually appealing results. From cotton and polyester to blends, each fabric responds differently to the printing process, providing a canvas for endless creativity.

Finishing touches

Once printing is complete, consider post-processing steps to enhance the final result. Heat pressing or curing the printed fabric will allow the inks to set and assure color fastness. Follow recommended guidelines for specific DTF ink and fabric combinations.

Continuous Learning and Adaptation

The world of digital textile printing is constantly evolving and new technologies and techniques are emerging. Stay informed about the latest trends, attend workshops, and participate in a vibrant online community to continually improve your skills and achieve even more amazing fabric prints.

Conclusion

Mastering the art of achieving vibrant fabric prints with DTF technology requires a combination of the right equipment, thoughtful design considerations, and a commitment to continuous improvement. By embracing the versatility of DTF printing, you open doors to endless creative possibilities, bringing your designs to life with unparalleled vibrancy and detail. Start your DTF printing journey today and witness the transformative impact on your textile creations.